Vehicle interiors are undergoing a profound transformation. Electrification, new user expectations and regulatory shifts are forcing OEMs to rethink not only the aesthetics but also the functionality and materiality of cabin spaces. Sustainability is no longer a nice-to-have; it’s becoming a strategic driver.

Rainer Süßmann, Executive Senior Vice President of the Business Area Plastic Decoration at surface finishing company Leonhard Kurz, explains to Automotive World how thoughtful material innovation can help OEMs meet tomorrow’s mobility needs without compromising on design or user experience.

The vehicle interior is becoming a decisive differentiator for car brands. What are the key challenges you see for OEMs in this area?

The expectations placed on interior design have fundamentally shifted. Today’s customers look for intuitive user experiences, sustainable materials, and a seamless integration of digital functions. At the same time, OEMs must meet increasingly strict environmental regulations while ensuring brand differentiation. The challenge lies in balancing aesthetics, functionality and sustainability, while also delivering on scalability and cost-efficiency.

In your view, how is electrification changing the design language of car interiors?

Electrification accelerates the move away from mechanical control elements and toward minimalistic, touch-based interfaces. Clean surfaces, customisable ambient lighting and novel materials are key elements in creating a distinctive, modern in-cabin experience. But it’s not just about visuals. Materials need to feel premium, perform reliably, and meet sustainability targets. That’s where intelligent surfaces come into play.

What should automakers consider when designing interiors that are truly future-ready?

Future readiness means aligning design with both emotional appeal and environmental responsibility. OEMs need materials that support their brand identity and contribute to carbon reduction goals and circular economy principles. Choosing the right partners and technologies early on makes all the difference when it comes to market agility and compliance.

What inspired your team to develop a new concept for a centre console for tomorrow’s mobility?

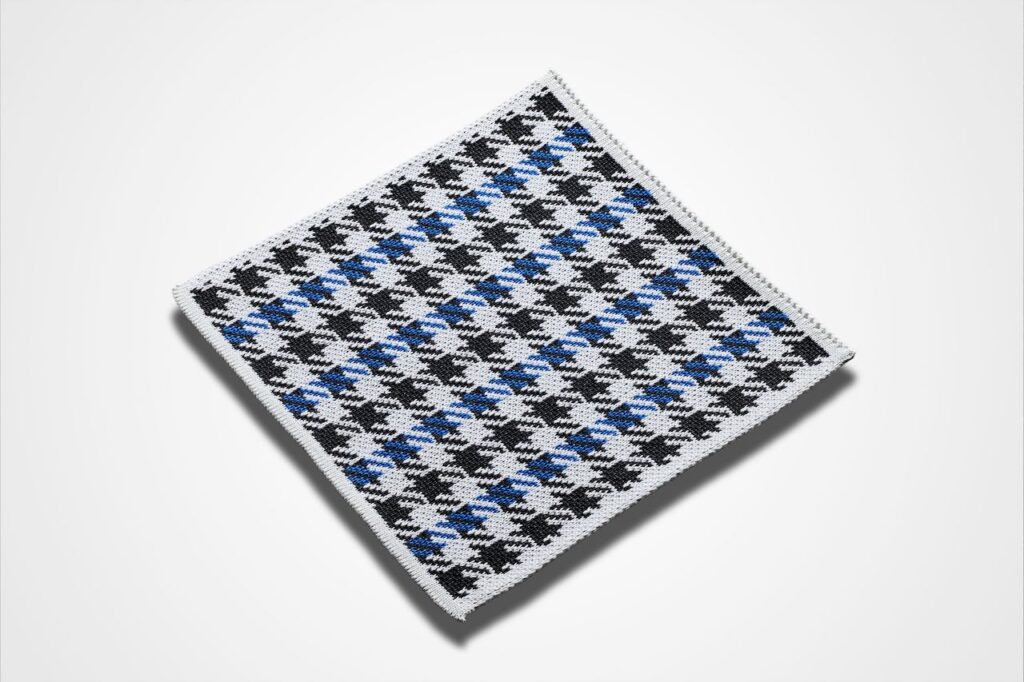

The transformation of car interiors is already in full swing. For us, the centre console developed in cooperation with our partner Farplas is a focal point to demonstrate how aesthetics, sustainability, and user interaction can be seamlessly combined. Our Smart Display Center Console was designed with a TRL 2–3 approach—conceptual, yet technically tangible—and uses technical textiles based on recycled polyethylene terephthalate (rPET). The rPET used in the concept is developed through our proprietary Recosys recycling system. In essence, it’s a vision of ‘beautiful sustainability’; a tactile, visual, and functional shift away from conventional materials like leather toward intelligent, recyclable surface solutions.

What are the main technological features of the demonstrator you are presenting at IAA Mobility 2025?

We’ve embedded capacitive multitouch sensors from our subsidiary PolyIC—completely seamless and visually clean. The touchpad includes a hidden-until-lit RGB matrix that reacts dynamically to user input, providing intuitive control with minimal distraction. Structurally, the console is designed for flexibility in shape, texture and coloration. What sets it apart is the way it combines sustainable design with digital functionality without compromising on durability or tactile experience.

How do your recycled textile materials meet the automotive industry’s requirements?

We’ve focused on a stable, scalable supply of high-quality rPET materials that fulfil automotive-grade requirements. The fabrics are not only recyclable but also transparently traceable, from source to surface. Thanks to our closed-loop system, we are developing a solution to offer OEMs a possibility to align with the EU’s recycling regulations and ESG goals, while enhancing their interior brand identity. The technical textiles can replace traditional materials, offering new design options without ecological trade-offs.

What value does this solution offer automakers from a brand perspective?

In a competitive market, differentiating through interior experience has never been more critical. The concept we are currently developing will provide OEMs with a sustainable, material solution for further processing that also enhances brand storytelling. It allows for versatile, customisable designs—visually and haptically—while documenting sustainability efforts in a verifiable way. It’s not just replacing one material with another but rather enabling new experiences that support the brand’s future-readiness and design ethos.

What are your next steps toward industrialisation?

The concept is currently at demonstration stage, and we’re working closely with partners like Topp Textil and Technofibres to advance industrial readiness. Our focus is on material validation, scaling of production processes, and integration into existing automotive supply chains. The interest we’re receiving confirms that sustainability is no longer a niche; it’s a design imperative. We’re helping OEMs put that imperative into practice with our solution.