Key technology for the internet of things

- Technological trends: a greater range of measurable variables and increased intelligence

- After cars and smart phones, now the internet of things is driving market growth

- Every second smart phone worldwide uses Bosch sensors

Micro-electro-mechanical systems (MEMS) sensors are indispensable in cars and smart phones today. These tiny sensors are becoming ever smarter, more compact, and more energy efficient. With help from MEMS sensors, even more things can become connected; in fact, anything can connect with anything else on the internet of things – including things that have never before featured electronics, such as windows and doors. This means more comfort, safety, and energy efficiency.

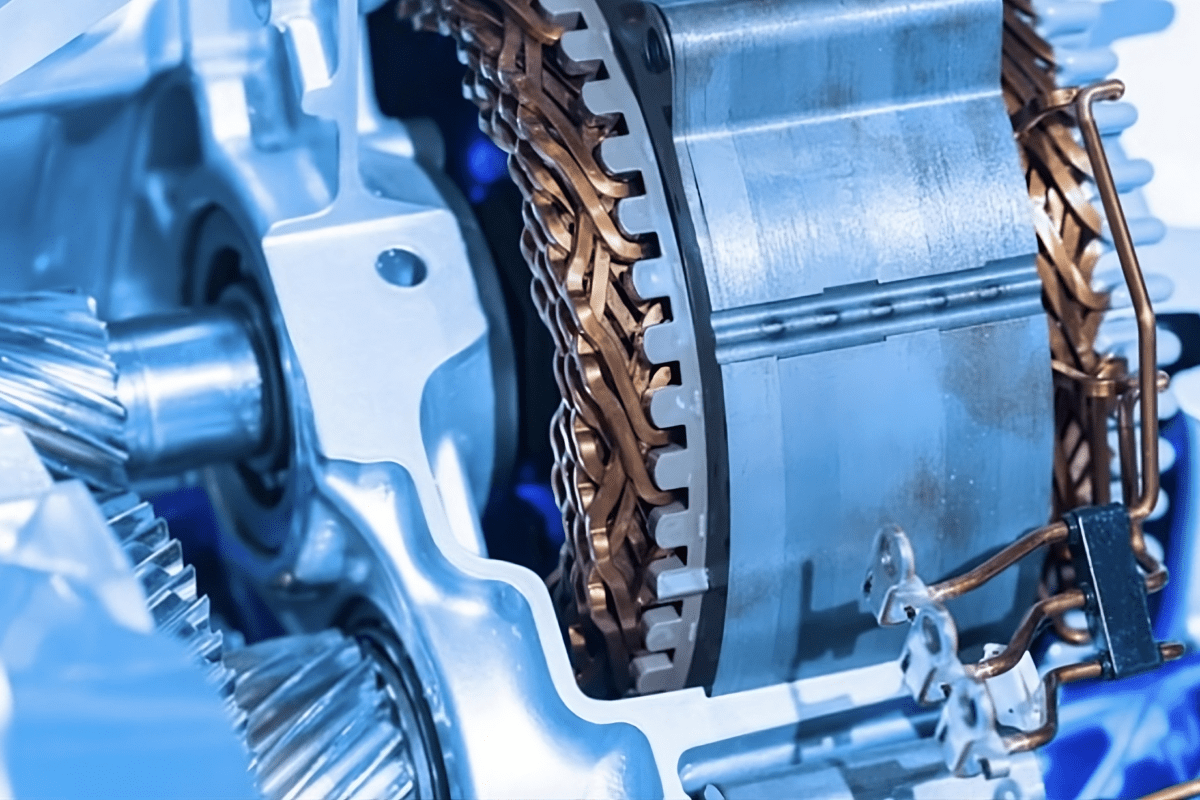

Bosch provides sensors for a range of uses in the automotive and consumer electronics industries. For instance, MEMS sensors measure pressure, acceleration, rotary motion, mass flow, and the earth’s magnetic field, and act as the sensory organs for cars or smart phones. Bosch has been producing these sensors for vehicles since 1995. A yaw-rate sensor that records the rotary moments around its vertical axis is at the heart of ESP, for example, and today each modern vehicle is home to up to 50 MEMS sensors. Thanks to Bosch Sensortec acceleration sensors, a smart phone or tablet knows how it is being held, and adjusts the image accordingly. Tiny MEMS microphones made by Akustica, a wholly-owned subsidiary of the Bosch Group, detect sounds and speech. Now every second smart phone worldwide uses Bosch sensors.

Bosch has been at the forefront of MEMS technology since it first emerged, and is the world’s leading supplier in this extremely dynamic market, as the experts at IHS Technology and Yole Développement have confirmed. Since the start of production in 1995, Bosch has manufactured well in excess of four billion MEMS sensors. In 2013, around one billion sensors emerged from its state-of-the-art wafer fab in Reutlingen – or three million each day. “Bosch is the only supplier that manufactures sensor types for so many different applications itself. Overall, Bosch holds more than 1,000 patents and patent applications related to MEMS technology to ensure we stay on top of our innovative capacity,” says Klaus Meder, president of the Bosch Automotive Electronics division.

Technological trends: smarter and capable of measuring more

MEMS sensors can measure an ever greater range of variables. In early 2014, Bosch Sensortec unveiled a world exclusive in sensor technology – the BME280 integrated unit, which combines sensors for pressure, humidity, and temperature in a single housing. The new unit was specially developed for applications related to environmental monitoring, indoor navigation, smart homes, personalized weather stations, and sports and fitness. Within a second, it can determine humidity – the fastest response time in the industry. It also offers remarkably precise measurement of ambient temperature and impressively low energy consumption. In addition, Bosch is making its sensors increasingly smart. Production is about to begin on the first sensor for measuring physical variables, such as acceleration, rotary motion, and the earth’s magnetic field, and it will also include a micro-controller for evaluating readings.

Key technology for the internet of things

The introduction of MEMS sensors in automotive electronics in the 1980s and 1990s marked the first wave of their surging popularity. The second major wave has been their widespread use in smart phones since the beginning of the 21st century – and the internet of things now heralds the third wave. Sensors, signal processing, batteries, and transmitters have become so small, energy efficient, and economical – even as all-in-one units – that they can be used in their billions. At the same time, radio networks are available almost everywhere. This makes MEMS the key technology for connecting things over the internet. MEMS must be equipped with a radio chip and a battery, and they must possess software intelligence, because only relevant data should be transmitted to the internet, not raw data. This local data processing calls for the special kind of systems expertise that Bosch brings to the table. In 2013, Bosch launched a door sensor that reports suspicious movements to the home owner’s smart phone. In the future, windows will control the heating or alarm system via unobtrusive sensors, and bracelets with embedded sensors will call for help if their wearer suffers a fall. Web-enabled sensor technology will be in everything that is “smart,” not just in smart phones.

Internet of things offers great business potential

A key aspect of Bosch’s future sales growth is web-enabled products and web-based services. The company considers itself well-positioned for such growth thanks to its hardware know-how and broad technological expertise. To unlock this business area, Bosch founded Bosch Connected Devices and Solutions GmbH at the end of 2013. It supplies compact electronic products and software expertise designed to make devices intelligent and web-enabled across a broad range of applications. The focus is on the development of connected sensors and actuators. Actuators convert electrical signals from sensors and control units into a physical action, such as automatically switching a light on and off or opening and closing a valve. Initially, business activities are concentrating on sensor-based applications for intelligently networked homes, or “smart homes,” as well as activities in the fields of traffic, transportation, and logistics – because in the future, consignments of critical goods will be able to transmit data on any unusual status changes directly to logistics centers.

Technical information about MEMS sensors

MEMS sensors contain the finest silicon structures. As the casing moves, these structures shift a fraction of a thousandth of a millimeter – and their electrical properties change in the process. These properties can be measured and converted into a data stream. The dimensions are incredibly small; while a human hair has a diameter of 70 thousandths of a millimeter (70 micrometers), some components measure only four micrometers – that is 17 times smaller than the diameter of a single human hair. Since the micromechanical sensor produces only weak electrical signals, the developers built in another electronic component – sometimes in the casing beside the sensor, sometimes even directly on the same chip. This second component processes, amplifies, and converts the weak signal into digital data. In this way, MEMS (micro-electro-mechanical systems) sensors can supply control units directly with readings.

More information is available online:

Sensors for increased safety in vehicles: new generation of Bosch inertial sensors

Simplifying development of airbag systems: new Bosch acceleration sensors

Bosch is top MEMS maker in 2013

Bosch sensors for automobile electronics

Bosch sensors for consumer electronics

MEMS microphones

Bosch sets up company for internet of things and services

Sensors – how technology maps the world around it

MEMS: the stars of the sensor world

Car-to-X: the future is about connectivity

Greater safety with peripheral sensors

Internet-enabled MEMS sensors

Videos:

Gyroscope for ESP: how it works

Pressure sensor: how it works

Acceleration sensor: how it works

MEMS sensor manufacturing

Bosch MEMS enabling the Internet of Things and Services