Vehicles are becoming cleaner and smarter, defined increasingly by their software. The rise of electrification and the trend towards automated driving are making them more complex than ever. At the same time, consumer expectations are pushing ever-shorter design cycles on par with connected personal devices like smartphones. Add in a shortage of skilled software engineers and tight margins, and the scale of the challenge becomes clear. For automotive design and engineering teams, the combination of advanced simulation technology, data and artificial intelligence (AI) could play a pivotal role in overcoming the design challenges in future mobility.

“It’s all about speed and cost, with companies pushing more into digital and less into people,” says Royston Jones, the Global Head of Automotive at simulation expert Altair. “New automakers are emerging all the time, and to stand any chance of commercial success, they need to get a product out on the market quickly. Often, they have a two-year target to successfully demonstrate something. The key to developing a differentiated product in that sort of timeframe is simulation.”

According to Market Research Experts, the global automotive simulation market was worth US$160bn in 2022 and will grow at a CAGR of 9.79% to 2028. Numerous players are jockeying for a slice of that market, including Altair.

Simulation meets AI

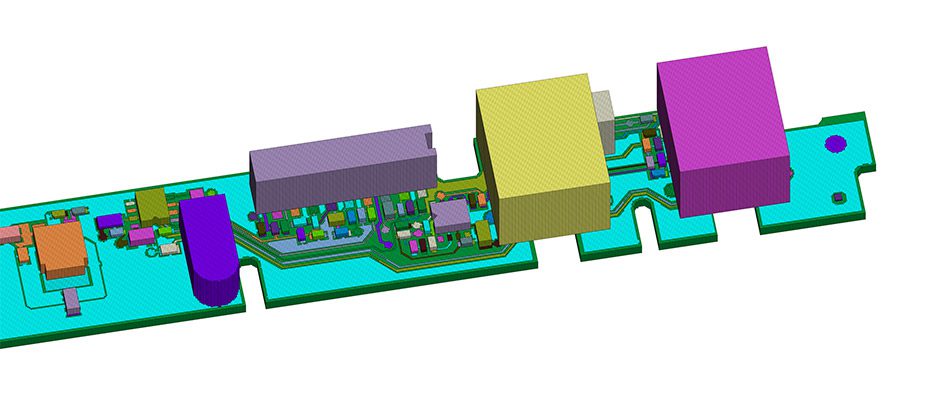

As well as expertise in simulation, Altair also specialises in computational science, data analytics and AI. “Our simulation software provides an assessment of all the various elements—structural, electric, thermomechanical, etc.—and wraps an optimisation layer around it,” he explains. “Our data analytics software helps with importing data and obtaining insights with machine learning. The offering’s third pillar is high-performance computing, which allows companies to manage this digital explosion in a controlled way.”

Altair has been helping companies make more informed decisions and optimise development for nearly 30 years, though its offering has evolved considerably during that time. Today it sees great potential from the fusion of AI with simulation, along with links between cloud computing and design optimisation, as well as data analytics and engineering. This sort of technology convergence could transform design outcomes for all sorts of projects. “New vehicles and their systems are becoming extremely complicated,” Jones emphasises. “It’s very difficult with all the various derivatives and permutations that teams are looking to generate.”

Six years ago, Altair began investing in greater data capabilities and has since poured more than US$500m into its data analytics solutions, including the 2022 acquisition of data analytics and AI platform RapidMiner. “Our Chief Executive, Jim Scapa, saw very early on the importance of tying simulation to computing and the impact that would have on the design process,” Jones explains.

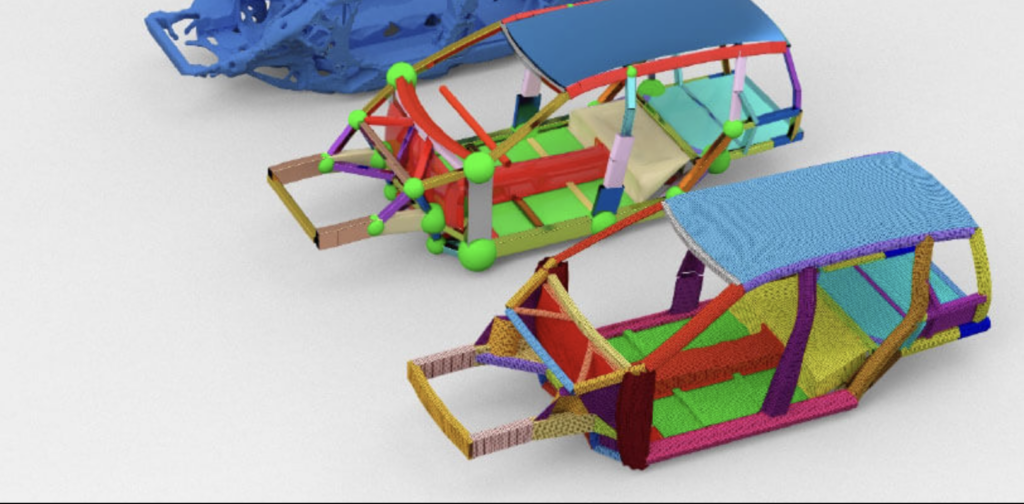

Towards zero prototypes

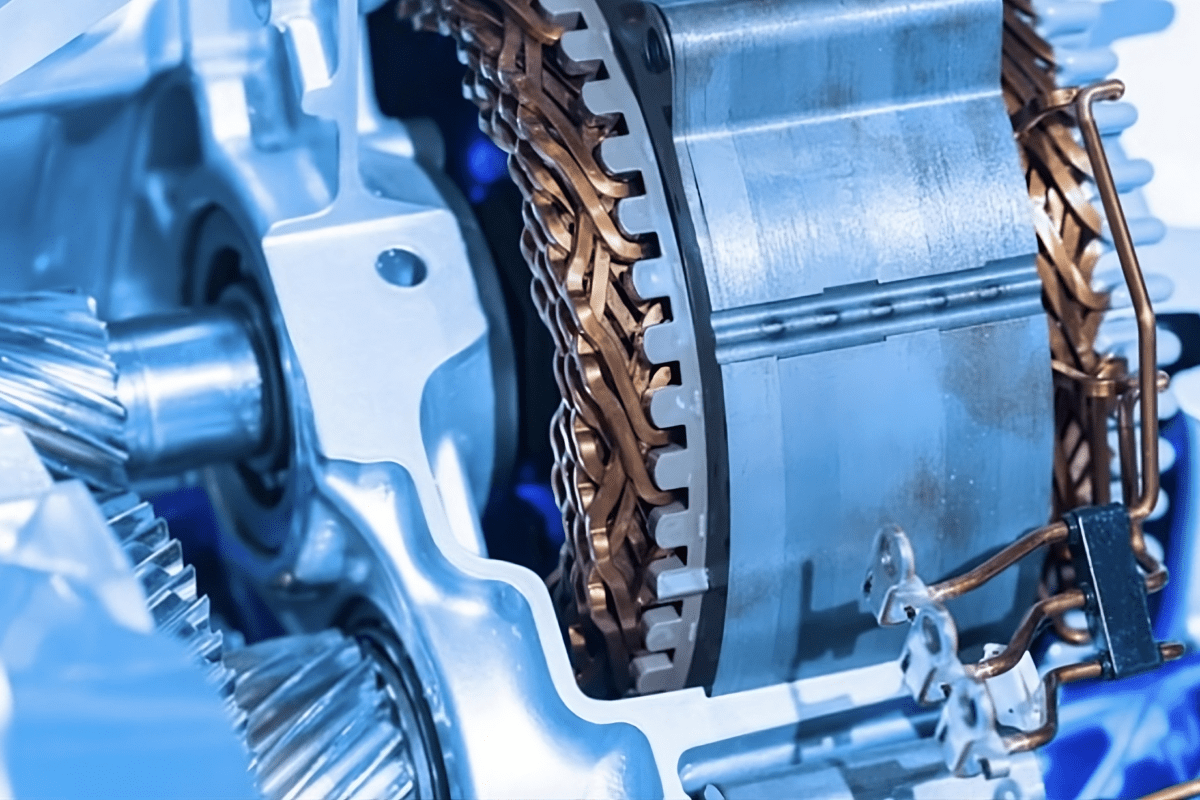

Altair is convinced that bringing together physics-based simulation-driven design with machine learning and leveraging high-performance computing opens the door to numerous efficiency gains across mechanical, electrical, and software design. This sort of tool is quickly becoming essential given modern vehicles’ level of complexity. “We are seeing a transformation of vehicles away from essentially mechanical components into more complex appliances, like smartphones,” says Jones. “They’re stacked out with software and offering a range of different types of powertrain.”

The aim of ‘zero prototypes’ is common among simulation solution providers, highlighting the power of digital and virtual development. “Loads and loads of prototyping would simply be infeasible given the sheer complexity of vehicles today,” he adds.

The EV impact

The move towards electrification is driving a huge demand for smarter development processes. After a century of experience with the internal combustion engine, manufacturers are now faced with rapidly mastering new design strategies around battery electric, hybrid and fuel cell powertrains. “The advent of electric vehicles (EVs) globally is perceived as lowering the barrier of entry, but that’s just the perception,” says Jones. “It’s easy to develop an EV; to develop a successfully commercial EV is a massive challenge.”

Loads and loads of prototyping would simply be infeasible given the sheer complexity of vehicles today

Altair is working with some big name players on this front. In the UK, it’s formed a consortium with Jaguar Land Rover and battery supplier Denecca to develop a new design process for EVs. The project, supported by funding from the government’s Faraday Battery Challenge, will use Altair design and simulation technology to develop prototype vehicles optimised for electric powertrains. Work kicked off in February 2023 and runs through the end of January 2025.

In India, it is collaborating with the Indian Institute of Technology (IIT) Madras to establish an e-mobility simulation lab. The lab is designed to provide start-ups, researchers, and students with state of the art tools to support R&D into electric propulsion. It will use Altair’s HyperWorks design and simulation platform.

“There is an amazing appetite to develop EVs at the moment,” Jones observes. “Simulation is going to get more intelligent, and we’ll be able to develop these vehicles even quicker.”

Further development

AI, computing and simulation are maturing rapidly, promising even more opportunities to reshape the design and engineering process. Down the line, Jones anticipates a massive evolution with digital twins: “We have long been creating virtual replicants of a physical world, but that will grow more and more intelligent until we have a smart twin of every vehicle coming off the factory line. And every car will be unique in some way simply due to tool ware or variability in its assembly. That twin will be available from the car’s birth to its death. That is the vision towards which we and many of our clients are driving.”

Altair’s client list covers the whole spectrum. “Essentially, we work with any company making product: OEMs, start-ups, suppliers,” says Jones. “In the future, maybe what we call an OEM will change.” He points to home electronics giant LG’s CES display of the concept car Alpha-able, featuring a range of innovative interior technologies that could redefine the user experience. “Then you have the phone makers—they already have all the key ingredients as cars transform away from mechanical to electronics and software. You can see them flirting with that type of product.”

Mobility is an ecosystem in flux, and the technology supporting new product development needs to evolve along with the products on offer. Altair’s three technology suites represent some of the tools on offer in the quest to develop more sustainable products, choose more sustainable manufacturing solutions, anticipate problems, reduce waste and carbon emissions, and improve reusability.