On the occasion of the VDI conference “Plastics in Automotive Engineering”, March 18 and 19, Mannheim, Germany

Flexible, light and safe

- Visible part: Novel engine covering made from flexible PU integral foam with the one-shot process

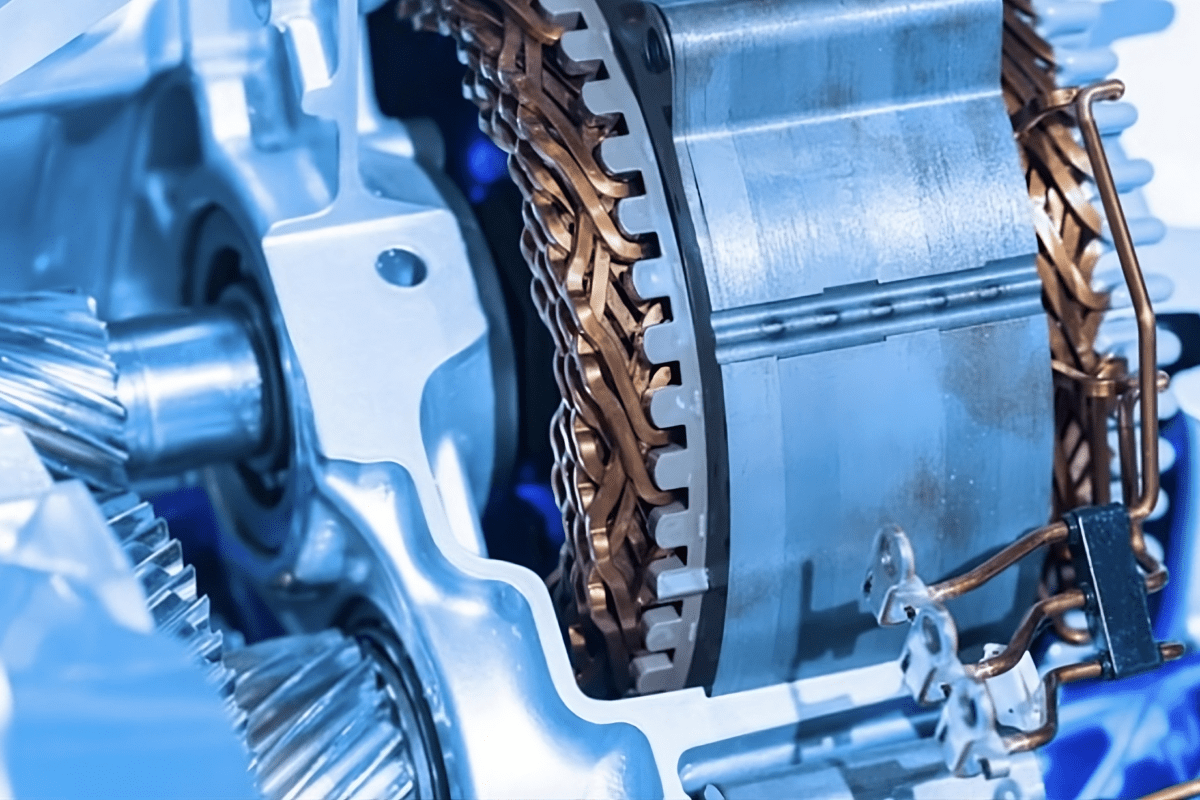

BASF has now developed a flexible polyurethane integral foam that can be used to produce lightweight engine coverings with the one-shot process, i.e. with one material in one process step. The so-called soft cover, made from Elastofoam® I 4603, is manufactured by the Austrian company POLYTEC Car Styling and fitted as standard in various car models with petrol engines of the Swedish automobile manufacturer Volvo. The sound-absorbing material for the flexible visible part is characterized by a low component density of 140 kg/m³, is dimensionally stable, media-resistant as well as resistant to thermal aging up to 150°C. With this novel component, BASF is supporting the automotive industry in reconciling the – often contrary – objectives of lightweight construction, functional integration and compliance with safety standards.

The tailor-made PU foam Elastofoam® I makes it possible to produce engine covers that are characterized by good sound absorption and thermal engine encapsulation. While the part has an open-cell foam structure on the bottom surface, the material on the front side forms a coherent skin with an attractive surface appearance. The surface is accurate in every detail and is printable. The part can absorb a lot of energy on account of the open-cell foam structure, thus increasing passive safety for pedestrians in the event of impact against the hood.

“Together with BASF, we have developed the part in such a way that material, production and functionality are optimally adjusted to one another. Moreover, we have achieved this in an unbelievably small amount of time. We can thus manufacture various geometries for different engine models and still simplify our logistics”, says Christian Schobesberger, responsible for technical development at Polytec.

Volvo currently uses the engine cover, which weighs from approximately 1.3 to 1.7 kilograms depending on the automobile model, in four different versions. The important thing is that the engine cover is light, shows good acoustic damping properties and has a high-quality surface. In comparison to conventional engine covers made of two materials, the elastic soft cover foamed in the cost effective one-shot process is able to integrate acoustic and mechanical properties in one part. This saves process steps during production, and better use can be made of the available space around the engine.

Plastics technology has gained great importance in engine acoustics. It plays an essential role in mitigating between lightweight construction and acoustics. BASF develops many plastics and processing methods, making engine covers more resistant, lighter and more space-saving. In addition to various PU foams, the portfolio includes the melamine resin foam Basotect®, engineering plastics such as Ultramid®, and the microcellular special polyurethane Cellasto®.