What the key trends and issues that are shaping the automotive industry of tomorrow?

I think the key topics have been the same for years. Fuel economy and emissions are the main two, related mainly to the powertrain, but increasingly also by the whole vehicle. E-mobility is also a significant topic that has been open to discussion for a while. However, there is increasing agreement that the future is not just going to belong to electric vehicles (EVs). Although they will certainly have a place, they will share the market with hybrid vehicles. The cost efficiency of hybridisation and 48 volt technology is a big issue, as is the continued improvement of diesel and gasoline engines.

In pole position in terms of current issues is the propulsion of the powertrain in general. But then you have the classic topics of aerodynamics, exhaust energy recuperation, board net optimisation, car to infrastructure and car to car communication and networking, and even autonomous driving coming into consideration. These all, in some way, come under the umbrella of improving fuel consumption.

An increasing awareness of the gap between real world fuel efficiency and official recorded figures has been evident across the industry for some time. What role does this play in FEV’s technology development?

Today, when we present technologies on fuel economy, we evaluate them not only in the NEDC but also in the new test procedure called WLTP. If we switch to WLTP, legislators will have to come up with a new figure that OEMs and suppliers are required to reach. The political discussion on whether or not these values are realistic is prominent. In my opinion, NEDC was primarily developed as a synthetic test cycle for pollutant emissions, and not to give the driver an indication of what fuel consumption he will have on the road. Real world driving is formed by the driver characteristics – those that are well trained to drive efficiently can benefit from a 25% – 30% saving in fuel consumption compared to those who drive fast or erratically. The optimisation of conditions during NEDC tests has allowed OEMs and suppliers to put a stamp on vehicles that will be difficult for normal drivers to obtain during real-world conditions.

Where do you see powertrain development heading over the next ten years and beyond?

I see a strong trend in the evolution of the passenger car diesel engine, where we will see much higher specific power. Engine downsizing will include further reductions in cylinder numbers, with related turbo charger and direct injection technology.

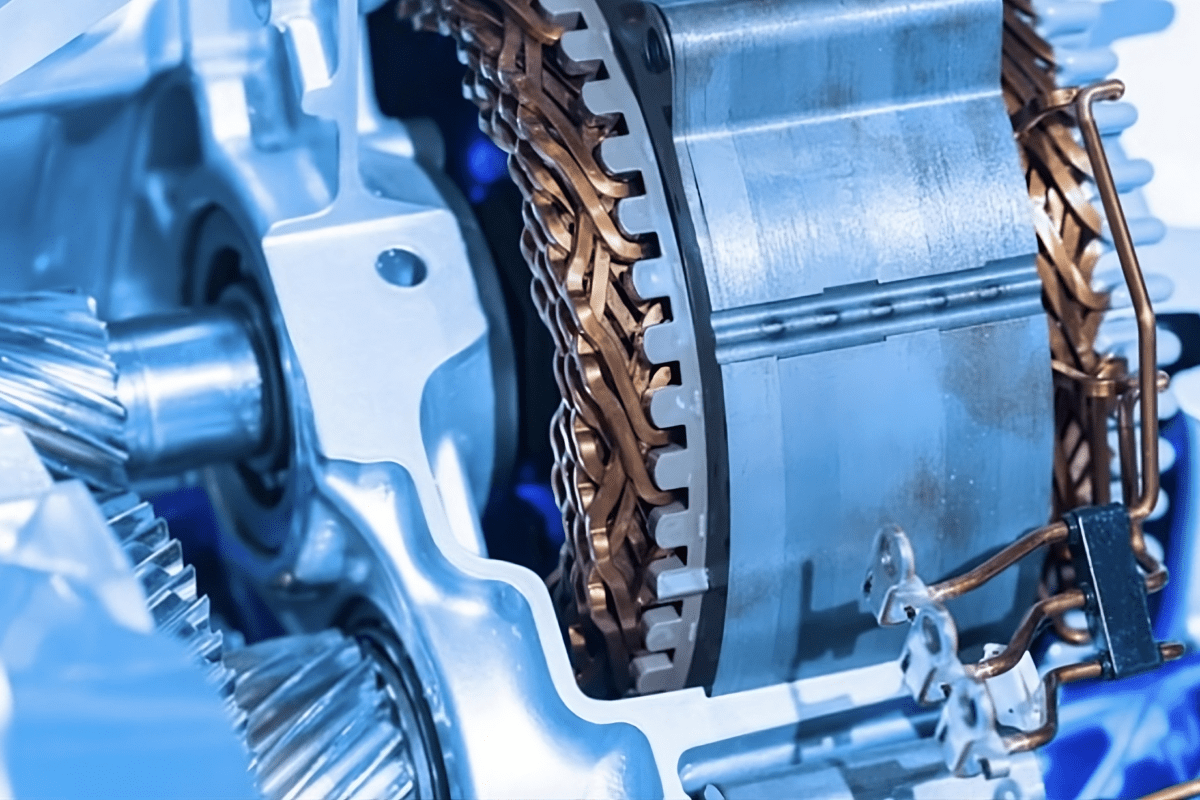

Friction reduction is another big issue in powertrain, and it will continue to be a big trend. Developments in roller bearings will help reduce friction dramatically, as we already see in turbo chargers, but we will see it in cam shafts and balancer shafts, maybe even in crank shafts. Innovations for variability will continue to come into powertrains, particularly variable compression ratio which we are bound to see in production within the next five years.

The adoption of natural gas in powertrains will continue, but at the same time we will reduce CO2 emission by 20% when using existing fuels through innovation and trends like engine downsizing.

What role do you expect plug-in technology to play?

Plug-in hybrids will penetrate the heavy vehicle segment in the next ten years. That is the way to go for heavier vehicles to meet CO2 legislation. EVs will probably be used more for urban vehicles and niche markets, often with some form of range extender.

Plug-in hybrids will penetrate the heavy vehicle segment in the next ten years. That is the way to go for heavier vehicles to meet CO2 legislation. EVs will probably be used more for urban vehicles and niche markets, often with some form of range extender.

I also think fuel cells in general will remain a niche technology in the coming years. They will not become mainstream, as it will take a long time to reduce their initial costs and they are extremely dependent on the growth of an entirely new hydrogen infrastructure.

How much life do you think is left in the internal combustion engine (ICE)?

When it comes to ships or locomotives, and even the heavy duty vehicle segment, where powertrains run for long periods of time under high load conditions, nobody sees an end to ICEs. If we focus solely on those drivers that only tend to travel short distances, the question is how many people are willing to buy separate, dedicated vehicles, just for the city?

If you want to have both, the solution will be plug-in hybrids, which means there is still an ICE included in the powertrain. There will be dedicated pure electric vehicles for the city, but there is certainly no end to ICEs on the immediate horizon.

How important is the integration of software into the engineering process of powertrains?

The big challenge in the engineering processes arises from the number of variants to be covered. Therefore we have to use software and its malleability, otherwise we will drown in millions of applications. Although software has made many processes in vehicle development more efficient, its complexity has made things much more complicated. Calibration also poses a big challenge, along with other factors like the safety and security of software. These can pose an interesting scenario for hackers who want to reach all the way down to your engine controls, or vehicle safety relevant applications.

As a result, FEV has many advanced research projects and numerous development projects in exactly this area. The ISO 26262 makes sure that we have really reliable software. To sum up, things are getting more and more complex, and we have to really make sure that all aspects of the vehicle are reliable and safe.