Software is increasingly defining how vehicles are designed and function. In some of today’s more advanced models, software alone can account for 40% of the total vehicle value, and McKinsey estimates that the global automotive software and electronics market will be worth US$462bn by 2030. But software-defined vehicles (SDVs) still rely on hardware, and the electrical/electronic (E/E) architecture deployed could make or break their success.

“The appropriate E/E architecture is the deciding prerequisite for an SDV,” says Joachim Fetzer, Chief Technology and Innovation Officer at Marelli. “It is the very starting point of SDV design.”

A future-proof architecture

The standard industry E/E architecture usually relies on a fragmented domain approach with numerous individual components, leading to increased complexity and potential inefficiencies. McKinsey estimates that platform design complexity is growing at a rate of 42% per year, while the effort required to deliver those platforms is increasing 36% at the same time. “Complexity is rising much faster than our ability to keep up,” observed Shannon Johnston, a Numetrics R&D Expert at McKinsey. “Teams are responding by spending more money and deploying more talent, but that is not sustainable.”

One response to the increasing productivity gap is to reduce system complexity, and that is pushing the move towards a more purpose-built SDV architecture. “A robust, scalable, and future-proof E/E architecture is crucial for the successful transformation to SDVs,” says Christoph Grote, BMW Group Senior Vice President for Software and Electronics. “It enables continuous software development, maximum reuse of existing software functionalities, and the integration of standardised and already existing components. This kind of architecture with future-proof performance allows for efficient deployment of new features across the entire vehicle line-up, enhancing the overall functionality of SDVs over many years.”

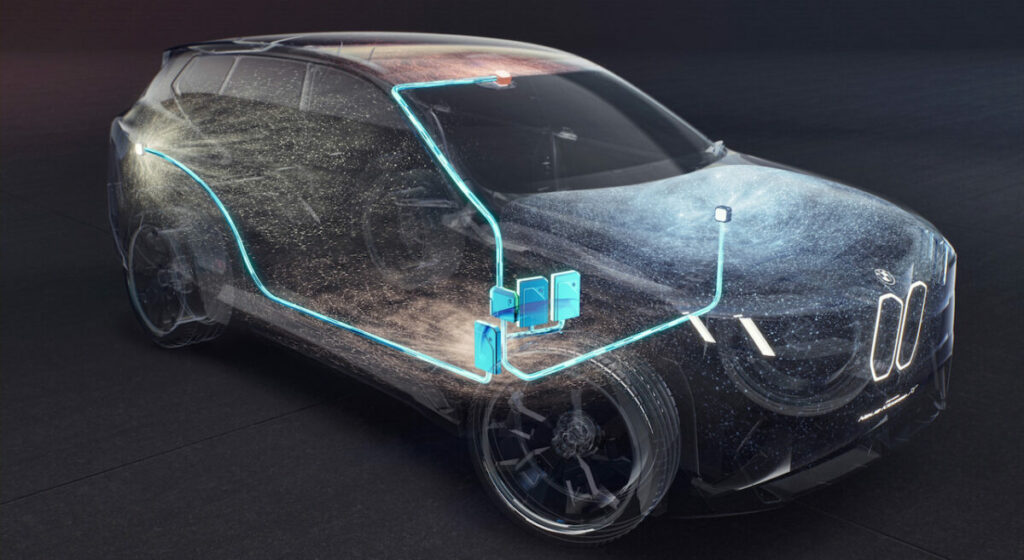

The favoured approach at the moment is a zonal architecture, in which a high-performance computer (HPC) in the centre of the vehicle is combined with several zonal modules. “The zonal architecture is much better than a standard architecture and offers more flexibility for overall vehicle improvement and functionality,” suggests Ruediger Ostermann, Vice President Chief Technology Officer of Global Automotive at TE Connectivity.

For Marelli’s Fetzer, a high-quality E/E SDV architecture comprises one or two HPCs, two to four zone control units (ZCUs) and a small number of electronic control units (ECUs), which are optimised without a specific microcontroller, to cover all vehicle functions. In the ideal setup, these microcontroller-free ECUs are connected via the CAN FD data-communication protocol with the ZCUs. “With this approach, the software is concentrated on the HPCs and the ZCUs, allowing massively shortened software development cycles based on digital twins,” he explains.

The ZCUs can also serve as power distribution units using smart fuses, reducing the complexity and weight of the wiring harness significantly. “A high-quality architecture also dramatically reduces the number of single function ECUs through consolidation into either ZCUs or HPCs,” Fetzer adds. “This highly consolidated architecture, which can be updated and upgraded over time through software updates alone, is what an SDV is all about.”

Grote describes a zonal architecture as “the current industry benchmark” and notes that such a design will launch in BMW’s next vehicle generation, Neue Klasse, starting at the end of 2025. It is characterised by the separation of a dynamic core (which provides a continuously evolving customer experience) from the static peripherals, which are vehicle-specific and often off-the-shelf solutions. Customer functions are implemented on unified software platforms for functional domains like Infotainment, ADAS, Driving, Body and Comfort.

“Managed and evolving APIs on different layers between functional domains, the application layer and hardware ensure seamless communication, backwards compatibility and modularisation, which offers the possibility to exchange components of the E/E system,” he elaborates. The peripherals are encapsulated by zone integration modules that handle data and energy management and implement hardware control functions, reducing the complexity and costs of the wiring harness.

Tangible benefits

Those cost and complexity benefits within the wiring harness are one of the biggest attractions of an optimised E/E architecture. “Traditional architectures are a system of complex wirings,” Ostermann tells Automotive World. “In an optimised E/E architecture, wiring becomes more organised, and wire lengths are shorter, leading to greater efficiency and less wire and wiring harness cost overall.”

This highly consolidated architecture, which can be updated and upgraded over time through software updates alone, is what an SDV is all about

It also creates knock-on effects. The Neue Klasse wiring harness saves up to 600m of wiring and shaves 30% off the weight of BMW’s current generation vehicles. Grote notes how the “weight reduction combined with advanced intelligent energy management made possible with eFuses make a substantial contribution to the 20% improvement in overall vehicle energy efficiency of Neue Klasse.” It doesn’t stop there: the new design allows for a high degree of automation when it comes to manufacturing the wiring harness, and a higher degree of common components leads to easier sourcing and a streamlined vehicle production process.

To put some more specific figures on the benefits of a good architecture, McKinsey evaluated 499 recent automotive projects divided into two groups based on architectural quality. This was based on a composite rating of the architecture’s fitness to satisfy application requirements, such as maintainability, scalability, reliability, testability, modularity, etc. “While it’s not particularly surprising to observe that well-defined and well-layered architectures are helpful, the magnitude of the impact may be surprising,” Johnston observes.

The team found that good architectures are associated with 23% shorter cycle times, 74% higher overall productivity, and 60% fewer defects. It’s this last metric that has Johnston particularly intrigued: “Increased complexity brings higher risk of failures and undiscovered defects. The cost of defects discovered in production or the delay of a model launch due to quality issues can be profound or even catastrophic. It’s important to recognise that high-quality architectures can reduce risk as well [as bring productivity benefits].”

A foundation for success

Industry players are full of advice when it comes to developing an E/E architecture that is innovative, efficient, and above all enables the benefits of SDVs. BMW’s Grote flags the importance of engaging in partnerships with technology providers, industry leaders, and open source projects to leverage shared knowledge and standards. For ZF, it involves developing clear roadmaps from the start. “Plan for the future by aligning E/E development with long-term objectives and customer expectations,” advises a ZF spokesperson.

While it’s not particularly surprising to observe that well-defined and well-layered architectures are helpful, the magnitude of the impact may be surprising

Fetzer also urges bringing the E/E architecture to the top of the design priority list: “Think of the vehicle design starting from the software architecture, as software is the defining component of the SDV.” He also advises developers to think about the vehicle at the system level, not the domain level, as this helps optimise the overall architecture in terms of compute allocation between HPCs and ZCUs. He even urges teams to organise their engineering department in a way that mirrors the E/E architecture and the respective software architecture “to avoid the potential pitfalls of Conway’s law.” This concept, introduced by computer scientist Melvin Conway, suggests that engineers produce designs that mirror the communication structures within their own organisations.

Looking ahead, the successful realisation of software-defined mobility will require multiple pieces to come together, and the E/E architecture is one of them. Getting that right isn’t a solution in itself, but it is a solid start. As Madhumitha Aravanan, Asset Leader at McKinsey, observes: “To unlock the SDV, you need to unlock the software, and the hardware—getting the E/E architecture right—is foundational to that.”