Diversified global manufacturer Asahi Kasei will unveil its newest innovation in PFAS-free polyamide (PA) and recycling technology of continuous carbon fibers at K 2025 in Hall 8a, Booth E23. The company will also showcase its diverse material solutions for automotive applications, improved connectivity, and lightweighting. K 2025, considered the world’s No. 1 trade fair for plastics and rubber, will take place during October 8–15, 2025, in Düsseldorf, Germany.

Asahi Kasei has developed a groundbreaking recycling technology that enables the recovery of continuous carbon fibers from CFRP (carbon fiber reinforced plastic) pressure vessels used in automobiles. Utilizing electrolyzed sulfuric acid, the process completely decomposes the resin matrix while preserving the carbon fibers’ original strength and continuous structure. Unlike conventional recycling methods that result in chopped fibers, this technology allows for the perpetual recycling of high-quality, cost-effective continuous carbon fibers from CFRP pressure vessels. At K 2025, Asahi Kasei will showcase over 200 meters of recycled continuous carbon fiber.

Asahi Kasei will also display PA and SEBS (hydrogenated styrene-based thermoplastic elastomer) compounds utilizing a bio-based and biodegradable cellulose nanofiber (CNF). This material is made from cotton linter and has high heat resistance and network-forming ability. CNF-reinforced polyamide becomes less viscous when agitated, making it highly suitable for 3D printing applications for easy printing, dimensional accuracy, smooth appearance, and mechanical performance. CNF-reinforced SEBS features a unique softness, which can be adjusted by changing the internal structure of the molded product. In addition, it shows a very low warpage and shrinkage, and good hydrolysis resistance. These properties make this material suitable for a wide range of applications, for example, jigs & tooling or prosthetics & orthotics devices.

In response to the increasing demand for PFAS-free materials, Asahi Kasei is developing a PFAS-free low-friction LEONA™Open new window PA and will introduce the new grade for the first time in Europe. Based on internal evaluations, the material has the same low-friction properties as fluororesin, making it suitable for sliding applications in various industries, including automotive, robot parts, office equipment parts, and sporting goods.

Materials for lightweighting and streamlined production of automotive parts

There has been a growing emphasis on reduced weight and improved design in automotive manufacturing. Asahi Kasei will display various technologies to address the most pressing concerns of automotive manufacturers at K 2025. One such solution is AZP™ transparent polymerOpen new window featuring almost no birefringence and light weight. It overcomes the challenges of conventional transparent polymers in applications with polarizing light, such as virtual reality and augmented reality devices and automotive head-up displays (HUD), while maintaining superior processability for large-scale production of injection-molded optical components. The company will exhibit an interactive automotive demonstration at K 2025 to showcase how AZP™ contributes to next-generation HUD.

Conventional approaches to automotive instrument panels, door panels, armrests, or center consoles have used different materials and production technologies for skin, foam, and core layers. Asahi Kasei’s SEBS![]() material is suitable for skin and foam layers, which can be molded in one step by utilizing a core back injection molding process, with strong chemical bonding between all the layers to eliminate the need for additional adhesive layers. SEBS contributes to reducing the total number of materials, simplifying the manufacturing process, and improving the recyclability of interior components.

material is suitable for skin and foam layers, which can be molded in one step by utilizing a core back injection molding process, with strong chemical bonding between all the layers to eliminate the need for additional adhesive layers. SEBS contributes to reducing the total number of materials, simplifying the manufacturing process, and improving the recyclability of interior components.

Another solution from Asahi Kasei that streamlines the manufacturing process for OEMs is SunForce™ mPPE (modified polyphenylene ether) particle foam beads. This material is well-suited to mass production of thin-walled, complex-shaped parts that require low tolerances, high heat stability, or UL94 V-0 flame retardancy. These properties make SunForce™ a perfect fit for thermal management solutions in electronic devices, transportation trays for Li-ion battery cells, insulation parts for HVAC equipment, and foam cores for FRP composite parts.

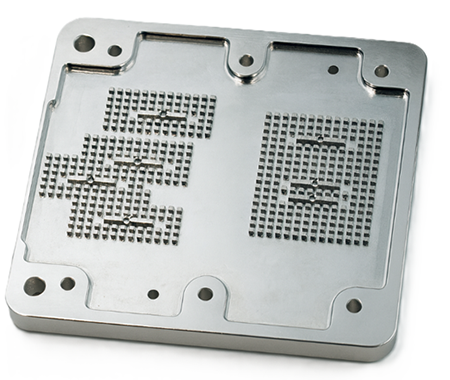

With the increasing number of radar applications across industries, the pressure to reduce material, production costs, and weight is rising. Slotted waveguide array antennas for automotive millimeter-wave radars are typically made of metal, requiring costly and time-consuming milling processes. Asahi Kasei’s XYRON™![]() mPPE features proven wet-platability, omitting the milling process and allowing for mass production of resin antenna parts via injection molding, which lowers cost and increases scalability.

mPPE features proven wet-platability, omitting the milling process and allowing for mass production of resin antenna parts via injection molding, which lowers cost and increases scalability.

Asahi Kasei will exhibit in Hall 8a, Booth E23. For more information, visit https://k-2025.asahi-kasei.eu

SOURCE: Asahi Kasei