April 23rd 2024

The economics of vehicle electrification

Latest articles

April 25th 2024

Toyota takes tighter control of Daihatsu

April 25th 2024

A distinctive in-vehicle UX could win over Gen Z and beyond

April 24th 2024

Software-defined vehicle forces a rethink around ‘recalls’

Automotive World Magazine

April 2024

Automotive World Magazine features the best and sharpest Automotive World content, curated specifically to help you understand the future of mobility

Special Reports

April 23rd 2024

The economics of vehicle electrification

April 9th 2024

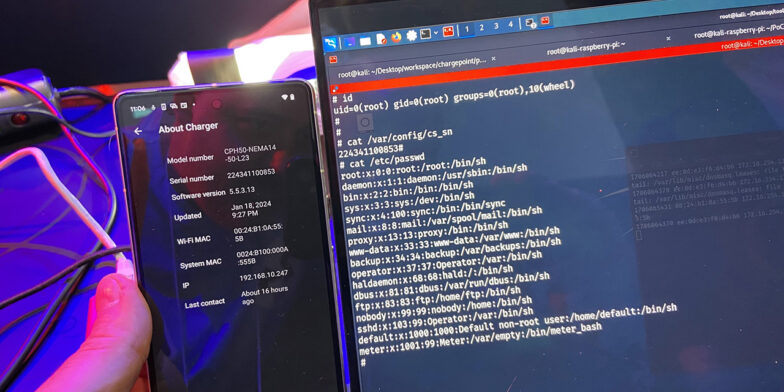

The evolving mobility cyber security landscape

March 26th 2024

The battle for mobility tech talent

OEM Model Plans

March 21st 2024

Honda Motor Company model plans and production forecast to 2028

February 15th 2024

Hyundai Motor Group model plans and production forecast to 2028

January 18th 2024

Toyota model plans and production forecast to 2028

Webinars

26th April

10am Stuttgart | 1:30pm Mumbai | 4am Detroit

Combustion modelling solutions for alternative fuels

IAV’s Michael Rieß presents an efficient 1-D simulation approach for predicting premixed spark-ignited combustion concepts based on future fuels such as ammonia, methanol and hydrogen.

2nd May

3pm Stuttgart | 6:30pm Mumbai | 9am Detroit

Building a safe foundation for software-defined vehicles with EB corbos

Elektrobit’s Joel Thurlby outlines the impact of functional failures and interference on vehicle functions and automotive software.

7th May

4pm Stuttgart | 7:30pm Mumbai | 10am Detroit

Next-level vehicle cybersecurity using ESCRYPT CycurHSM on AURIX™ TC4x devices

Rohan Pandit of ETAS and Infineon’s Michael Arzberger and Laurent Heidt discuss the complexities of balancing cybersecurity, performance, and cost-effectiveness in today’s competitive market.

8th May

4pm Stuttgart | 7:30pm Mumbai | 10am Detroit

Beyond battery cycling basics – how to verify design, compliance, safety, and production with validation planning and analysis

Element’s Mike Pendleton explains how battery design verification and analysis can help answer questions before they arise and how to save costs in design and production validation cycles.