What distinguishes companies that are making rapid progress in digitalizing their manufacturing operations from those that are not? The new Roland Berger study on “The current state of Industry 4.0” has found that it is a combination of four factors: the clear prioritization of applications, the setup of a dedicated cross-functional Industry 4.0 team, the definition of a completely harmonized IT/OT target landscape and a strong focus on respective employee training. Drawing on the experiences of leading automotive OEMs and Tier-1 suppliers, the study presents the key success factors for digital manufacturing.

“When the term ‘Industry 4.0′ was coined a good ten years ago, there were immense hopes around it,” says Bernhard Langefeld, Partner at Roland Berger. “In the meantime, companies have in some cases invested a lot of money, but most of them are still far away from the original vision of an intelligent, fully flexible and self-organizing factory.”

Digital manufacturing often fails in practice owing to circumstances such as largely autonomously operating production sites with heterogeneous IT/OT architectures, the use of outdated equipment, or difficulties quantifying the added value of Industry 4.0 use cases. In spite of these challenges, the automotive industry in particular has made significant progress in Industry 4.0 in recent years. The consultants’ analysis based on the experiences of leading manufacturers and suppliers shows that to drive the identification, prioritization and implementation of use cases, the digital pioneers rely on organizational setups that efficiently enable a centralized (hub-and-spoke) approach to solution development. This avoids the same work having to be repeated at different company facilities. Not only that, but the resulting processes are easier to roll out and scale up across multiple plants if there is one central body in control.

Organization and technology are crucial

The implementation of individual use cases requires competency in data analysis, IT and production. That is why successful OEMs normally bundle their digital activities on a cross-functional basis in an Industry 4.0 center of excellence. Working in close coordination with the plants, this central team will determine the concrete requirements and pilot new applications. To manage the various specific implementations, companies also need an overarching IT/OT target architecture. This is where IIoT-based cloud platforms are becoming increasingly important. This target landscape helps to avoid the redundant buildup of IT infrastructure and interfaces for different use cases, and ensures that the use case implementation roadmap is aligned with the investment in new systems.

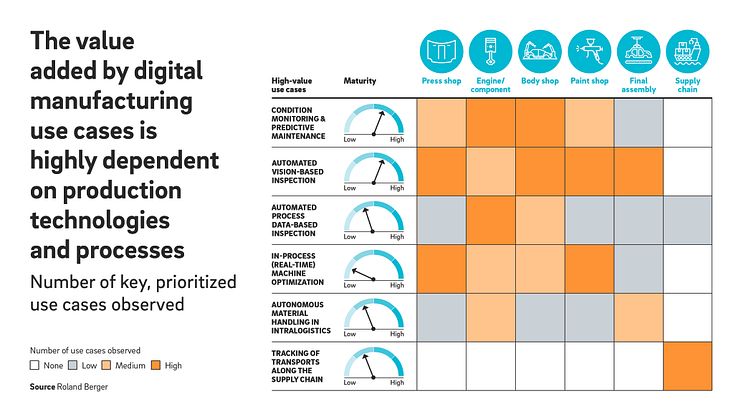

The study found that the automotive industry has achieved considerable success in recent years:

- Condition monitoring and predictive maintenance of plant and machinery are already at an advanced stage of technical maturity.

- Vision-based and process data-based inspections come with high value added across different use cases, from engine production to final assembly.

- Autonomous material handling is used particularly in intralogistics for engine and vehicle assembly.

- Modern track and trace systems support the tracking of transports along the supply chain, helping to achieve greater process transparency and facilitating the seamless tracking of incoming parts.

- In-process (real-time) machine optimization displays the lowest degree of technical maturity. There are currently some initial pilot use cases in press and paint shops.

SOURCE: Roland Berger