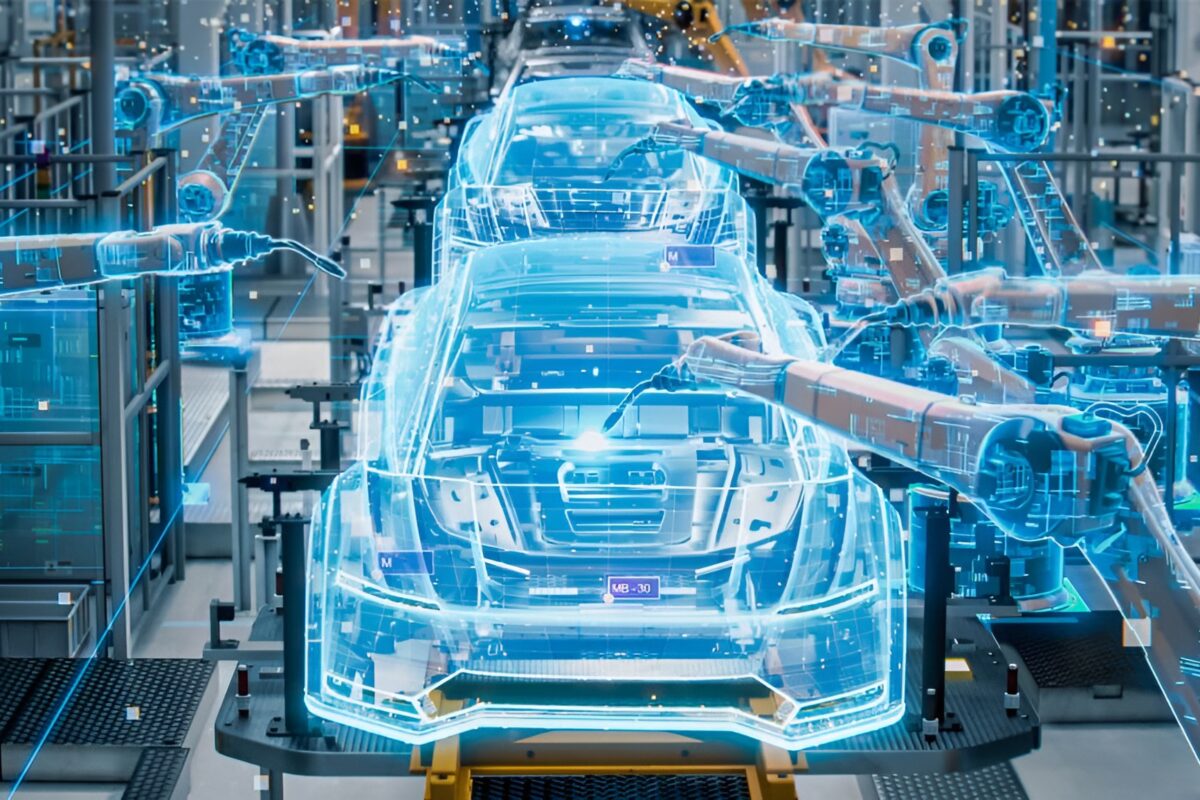

Automakers are showing greater interest in implementing their own LTE/5G networks on the factory floor. The investment promises reliable, high-speed and low-latency wireless connectivity for IoT sensors, plant machinery and connected vehicles. Manufacturers are using these networks to upload IoT data directly to vehicles as they roll off the line as well as to support smart networking of robots and wireless assembly tools.

|

Ford recently installed a private mobile network to capture data from sensors installed across its electric vehicle (EV) plant in Essex in the UK. This allows it to monitor the end-to-end production process and respond quickly to changes. Similar investments are in place or underway by many other big name players like Ford, Volkswagen and General Motors, and the number of such private networks is poised to grow significantly in the coming years. Some predictions call for private LTE/5G networks in 75%-85% of all manufacturing facilities by 2024 or 2025.

As numbers grow, the importance of securing such networks comes under the spotlight. OneLayer specialises in cellular security for private networks. Its platform draws on expertise from both cyber security and cellular technology to help companies address vulnerability in their networks. Dave Mor, the Chief Executive of OneLayer, speaks to Automotive World about the importance of securely connecting factories as they transition to a connected future.

It’s time to log in (or subscribe).

Not a member? Subscribe now and let us help you understand the future of mobility.

Scroll

News

Magazine

Articles

Special Reports

Research

OEM Tracker

OEM Model Plans

OEM Production Data

OEM Sales Data

1 user

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- no

- OEM Tracker

- no

- OEM Model Plans

- no

- OEM Production Data

- no

- OEM Sales Data

- no

1 user

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes

Up to 5 users

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes