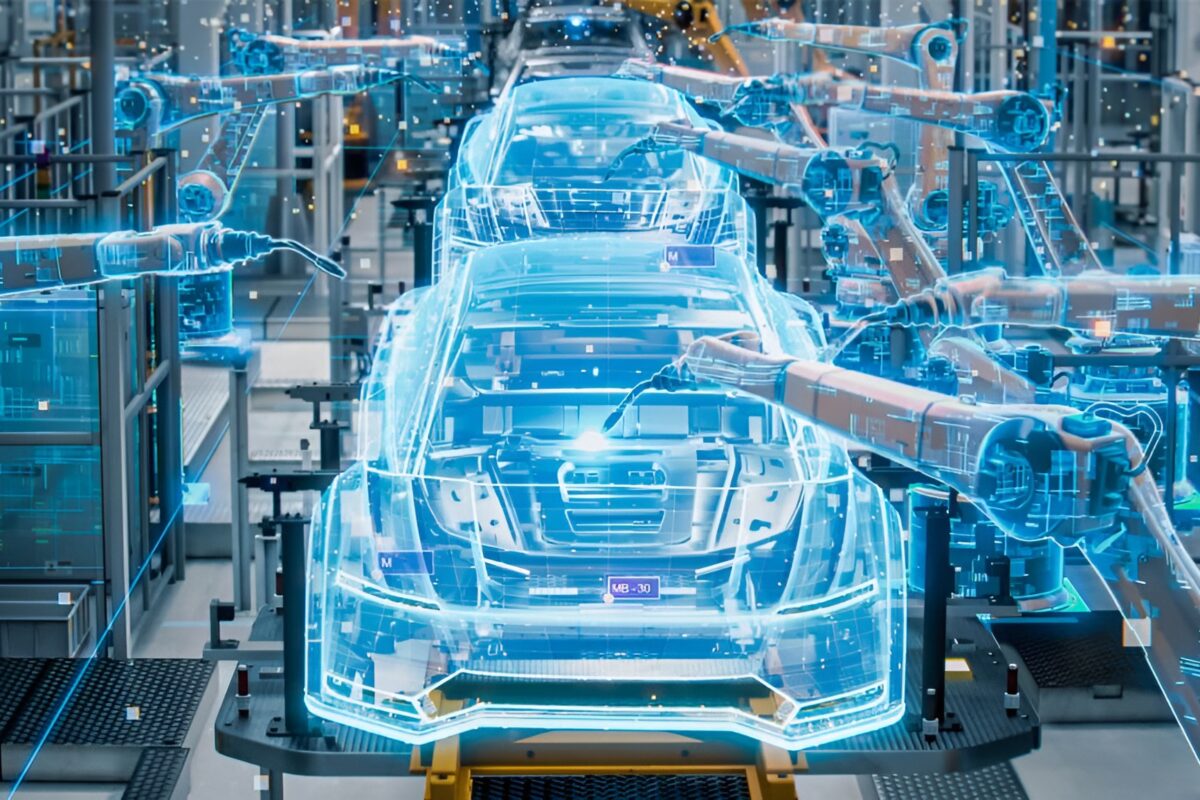

Digital technology is helping companies reinterpret the basic principles laid out under the Toyota Production System (TPS). A range of connected systems combined with advances in data analysis are allowing manufacturers to upgrade the traditional TPS values of waste elimination, process optimisation, defect detection and constant improvement. The whole idea of robotisation or computerisation itself is an essential ingredient to the Toyota philosophy, as epitomised under the jidoka concept of 'automation with a human touch'.

It’s time to log in (or subscribe).

Not a member? Subscribe now and let us help you understand the future of mobility.

Scroll

News

Magazine

Articles

Special Reports

Research

OEM Tracker

OEM Model Plans

OEM Production Data

OEM Sales Data

Most Popular

Pro

£495/year

or £49.50/month

1 user

1 user

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- no

- OEM Tracker

- no

- OEM Model Plans

- no

- OEM Production Data

- no

- OEM Sales Data

- no

Most Popular

Pro+

£1,950/year

or £195/month

1 user

1 user

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes

Most Popular

Pro+ Team

£3,950/year

or £395/month

Up to 5 users

Up to 5 users

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes

Most Popular

Pro+ Enterprise

Unlimited

- News

- yes

- Magazine

- yes

- Articles

- yes

- Special Reports

- yes

- Research

- yes

- OEM Tracker

- yes

- OEM Model Plans

- yes

- OEM Production Data

- yes

- OEM Sales Data

- yes