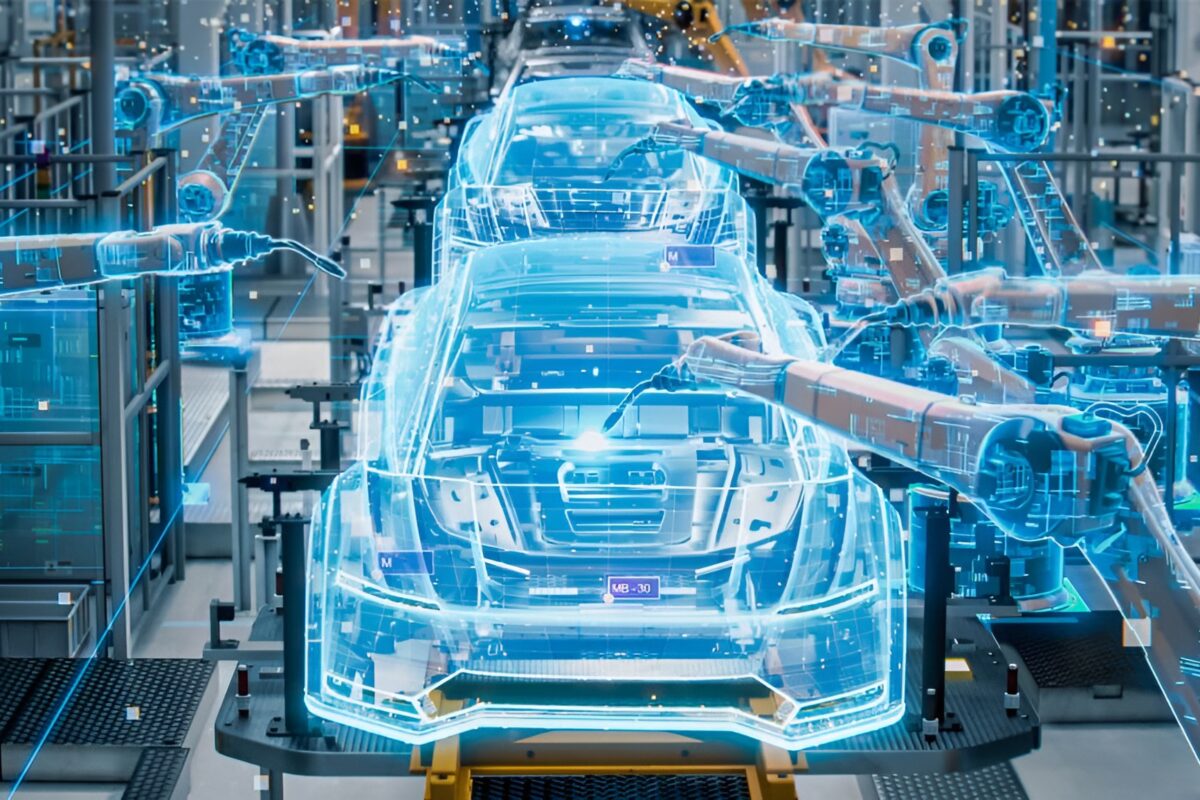

Issues such as regulatory uncertainty and compliance with safety certification standards will pose a significant challenge to autonomous vehicle (AV) developers, as well as a handful of more immediate concerns around the technology itself. Automakers have poured investment into R&D, but lofty hardware and software costs remain. If AVs are ever to hit the market en masse, slashing those costs and ensuring functional safety standards are met will be key.

In March 2019, an investigation was commissioned to learn more about the challenges hindering the delivery of safe and affordable autonomous vehicles at scale. The report, led by Forrester Consulting and commissioned by global semiconductor IP firm, Arm, surveyed workers across the AV space: the vast majority of respondents (90%) work for companies developing SAE Level 1 to Level 4 AVs; the remainder focus on Level 5 vehicles which, in theory, will be able to operate in any given scenario, condition and environment without a driver.

The report shows that while the industry is largely bullish on the outlook for AV technology—with steady progress being made—there are numerous hurdles to moving such prototypes into series production. The findings offer an honest and frank insight into the challenges being faced at the front line, and for Arm it is an opportunity to put its expertise in semiconductors, software and services to best use.

“We are really trying to figure out what Arm has to do in order to meet those requirements going forward,” said Robert Day, Director, Automotive Solutions & Platforms at Arm. “It is about understanding how developers can move from prototypes to a product that is actually deployable. We are in conversation with the OEMs, Tier 1s and wider automotive industry to try and understand the challenges they are facing.”

Cutting costs

In gauging the AV industry’s temperature, a number of concerns have become clear. From a technology perspective, it is proving a challenge to develop increasingly precise sensors and greater compute power, whilst continuing to reduce costs.

The element of cost efficiency is crucial for any mass-produced product, and developers are currently held back by expensive systems and components. Based on the Forrester survey, high component costs are the single biggest challenge facing the development of a prototype AV system. Illustrating this is the fact that only 20% of respondents confirmed they have a reliable prototype being prepared for production.

It is about understanding how developers can move from prototypes to a product that is actually deployable. We are in conversation with the OEMs, Tier 1s and the wider automotive industry to try and understand the challenges they are facing

Part of this may also come down to the approach. Day argues that many AV developers are unsure of the compute power required, and end up “throwing a ton of it at the vehicle” whilst developing their software in parallel. “The problem is that people are not considering the factors that will make the prototype deployable, one of which is cost,” said Day. “If you throw a ton of servers in the back of your car, that’s not very cost effective. Then you have considerations of power, thermals, size and everything else—all of that has to change in order to be deployable.”

It is not just compute power that ramps up cost, but also the integration of sensors. In particular, LiDAR—a laser scanning technology that models the vehicle’s surrounding environment—has proven to be an expensive addition to the suite that typically includes cameras, radar, infrared and occasionally high definition (HD) maps. “The problem is that right now, the higher the level of precision you need, the more costly the sensors become,” said Day.

LiDAR costs have gradually come down in recent years, and a number of start-ups have introduced entry-level systems that go for hundreds of dollars as opposed to tens of thousands—early LiDAR sensors are said to have cost as much as US$75,000 per unit. “Bringing overall system cost down is one of the key areas that Arm is really trying to help with,” affirmed Day.

Get functional

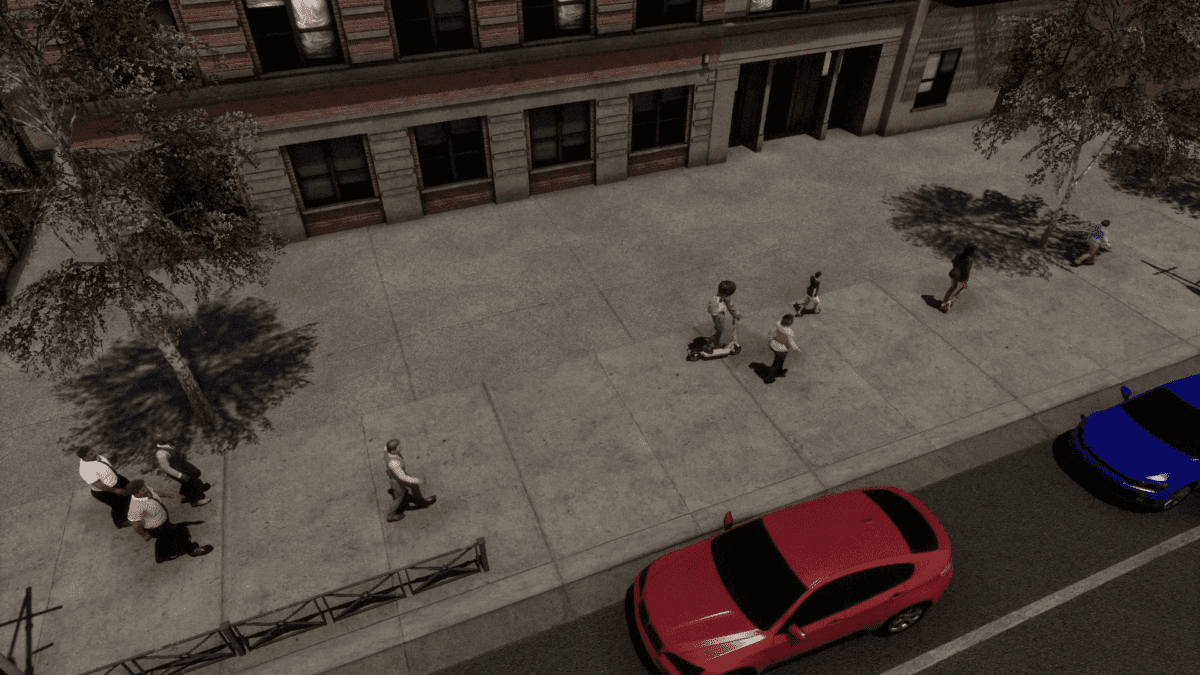

The challenge does not stop once the hardware has been installed. Developers also need to figure out how to process all of that resulting data, and how to use it in a meaningful way. In addition, they need to ensure that functional safety is taken seriously. “One of the key things that came out of this report is the requirement for functional safety,” affirmed Day. Indeed, functional safety and reliability are a chief concern for those surveyed, with 48% highlighting the creation of a reliable system as the most important element for a production-ready design.

We enable people to build fit-for-purpose SoCs using different elements of our IP. This means they are less expensive, use less power, have a high level of safety and are ultimately more deployable

As the vehicle becomes tasked with making decisions that would once have been left to the human driver, those systems need to operate as intended and without fail. “These autonomous systems are going to make decisions about where the vehicle goes, whether it stops, accelerates or changes lane—and they’re all safety functions,” said Day. “If the system gets it wrong, people could die, so the industry is making sure that they operate in a safe way.”

While Arm does not manufacture chips per se, it is one of the largest global players in the semiconductor and microprocessor space. By licensing its IP to the wider industry—working with dedicated chip-makers, Tier 1 suppliers and automakers—it is playing a key role in the development of purpose-built Systems-on-Chips (SoCs) for AVs. Today, these chips power the increasingly complex systems in modern vehicles, from driver assistance functions and in-vehicle infotainment (IVI) systems, all the way to full AV prototypes.

Rather than taking an off-the-shelf, general purpose chip, explained Day, Arm can ensure that manufacturers optimise what goes into their architecture. “Many AV developers are just adding racks of general purpose CPU or GPU computing, but we enable people to build fit-for-purpose SoCs using different elements of our IP,” he said. “This means they are less expensive, use less power, have a high level of safety and are ultimately more deployable.”

For example, last year Arm launched its first multi-threaded CPU designed specifically for automotive use. Able to handle a large number of data streams, it is well suited to enabling what is known as ‘sensor fusion’, where data from each individual sensor on the vehicle is combined and leveraged by the self-driving computer. “These kind of processors essentially have functional safety built in,” added Day.

Partner up

The move toward autonomous vehicles has shaken up how stakeholders are working together. Once fierce competitors are now collaborating openly in the pursuit of a shared goal, and it has become clear that automakers cannot go it alone. This is true across the industry, and illustrates the inherent challenge of getting up to speed with unfamiliar forms of hardware, software and business models.

At Arm we are facilitating some of that collaboration by offering a standard architecture, which can be leveraged regardless of the chip-maker or Tier 1 in question

Arm believes it is well placed to help players across the value chain—from chip-makers and software developers to Tier 1s and automakers—meet the challenge of taking AV prototypes to series production. “At Arm we are facilitating some of that collaboration by offering a standard architecture, which can be leveraged regardless of the chip-maker or Tier 1 in question. From there, they can implement this technology how they normally would,” explained Day. “We have to take a higher level view of the issue; there are common challenges that everyone is facing—regardless of whether they are developing independently or collaboratively—and we can help to address those issues.”

According to the Forrester report, forging partnerships will be key to bridging hardware and software challenges moving forward. The majority of respondents indicated that their autonomous driving software uses a mixture of commercial software that has been purchased from a third party, open source software, and that which has been developed in-house. As the report concludes: “Only a few firms have the resources to go it alone entirely. Almost all firms should seek suppliers and partners to round out proprietary and specialised in-house technology with complementary professional services, software, sensors and compute designs.”

To learn more about Arm Autonomous Drive Solutions, click here.