Electric, connected and autonomous vehicles are driving a seismic shift in the automotive industry. We are witnessing major market disruption with new players entering the space, and an overhaul of manufacturing models on a scale akin to the transition to ‘just-in-time’ manufacturing 60 years ago. Companies including Apple, Sony and Foxconn have already entered the electric vehicle (EV) market and Tesla has established itself as a digital-native global manufacturer, while EV start-ups such as Arrival are pioneering new manufacturing models involving the end-to-end digitalisation and automation of production in a single micro factory.

The market is facing radical disruption because the rapid pace of EV development requires new smart manufacturing approaches and components outside the traditional automotive supply chain. Consumer technology giants already provide many of the electronic and software components needed for EVs and these digital natives are also far ahead of conventional carmakers in the Industry 4.0 technologies that are increasingly essential to EV manufacturing. At the same time, barriers to market entry are now lower because EVs have fewer mechanical parts than internal combustion engines (ICEs) and have made many automotive parts, processes, patents and elements of the supply chain redundant.

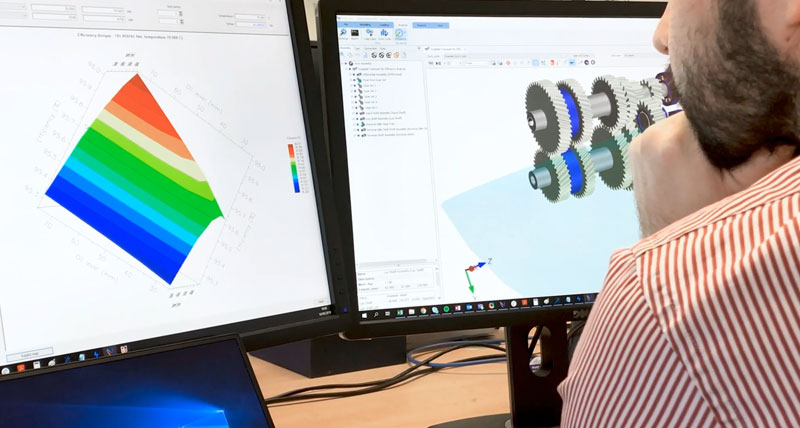

For example, the need to deliver an energy efficient and cost-effective product quickly requires digital consolidation of design, engineering and manufacturing and closer supply chain collaboration with a growing imperative to vertically integrate key system production in-house. EVs also require digitally integrated manufacturing approaches to design complex software, electronics and automotive parts as a cohesive ‘system of systems.’

The need to achieve parity of price and performance with ICEs while remaining profitable and sustainable also requires that new product introduction processes are supported in shop floor transformations that can help achieve the required efficiencies across every part of the car and the production process. It is only when development and manufacturing work hand-in-hand that the flexibility and productivity of smart manufacturing can be truly realised. But that’s not to say anyone—start-up or established automaker—is ready today, and the race to realise this is inextricable from the race to bring winning EV models to market.

Findings from Hexagon’s recent survey reveal concerns over low order volumes and inability to reach economies of scale. This, combined with the pace of EV innovation required to avoid being late to market, means that speed is increasingly replacing scale as the success factor in automotive manufacturing.

Surprisingly, the survey reveals that automakers are failing to make the necessary transition to smart manufacturing approaches and are unconcerned by disruption from new market entrants that favour agile, adaptable manufacturing processes more akin to DevOps practices in cloud software than to more traditional linear development and assembly lines. Over half the automotive industry states that they are not increasing investment in smart manufacturing technologies, with 25% sticking to current spending levels and 25% planning no investment, yet the data also reveals the same panel do not see pure EV players as a threat. Complacency and sluggish adoption of smart manufacturing could leave traditional OEMs blindsided by new market entrants from the consumer tech industries that specialise in speed to market that is enabled by a smart manufacturing strategy and technology stack.

If market incumbents are to avoid the risk of being eclipsed by new EV manufacturers, they need to actively embrace the current disruption of automotive manufacturing models. This necessitates the breaking of traditional silos between disciplines and greater digital integration and automation of manufacturing workflows from concept to customer. Some OEMs are too big to fail and many start-ups won’t last five years, but we are at a time of real change and the smart manufacturing innovators are successfully leading this transition by connecting end-to-end automotive manufacturing design to engineering and manufacturing to make better decisions using virtual and real data to maximum effect.

The opinions expressed here are those of the author and do not necessarily reflect the positions of Automotive World Ltd.

Ignazio Dentici is Vice President, Global eMobility at Hexagon’s Manufacturing Intelligence division

The Automotive World Comment column is open to automotive industry decision makers and influencers. If you would like to contribute a Comment article, please contact editorial@automotiveworld.com