What has a human form, a steel skeleton, rubber skin, and costs in excess of €100,000 (approx. US$125,000)? If you haven’t guessed, the answer is a crash test dummy.

Coming in many sizes and ages, crash test dummies act as calibrated test instruments and are intended to simulate human response to impacts, accelerations, deflections, forces and moments generated during high-impact crash testing, while offering vehicle designers a safe, repeatable test instrument for the furthering of transport safety.

The way crash test data is gathered and interpreted through dummy testing has come a long way since the practice began in the 1950s, but the basic principles of using dummies for monitoring the way humans might be injured in a crash remain relatively unchanged.

Becoming biofidelic

Modern test dummies must be designed to enable several variables to be recorded, like crushing force, bending, folding and deceleration rates during a collision for use in crash tests, and different types of dummy are required to test the multiple areas of impact that would affect a passenger in a crash such as frontal or side impact.

Transducers fitted into the body, for example the rib cage and the head, provide the physical levels experienced by the dummy. These readings are controlled and repeatable due to careful dummy design, calibration and manufacture so that the vehicle designer may use them to perfect the safety of his product.

20 years ago, GM’s Hybrid III dummies officially became the industry standard for testing to comply with the US government’s frontal impact regulations and airbag safety. The development of Hybrid III served as a biofedelic launch-pad to advance the study of crash forces and their effects on human injury, but as technology and materials develop over time, more accurate and human-like dummies have begun to emerge.

Dummies have become increasingly biofidelic – that is, they replicate key human physical characteristics including size and shape, mass and energy absorption – using more realistic body parts, such as shoulder and thorax through feedback from real world crashes and cadavers. The biggest upcoming change for dummies is an update of the frontal Hybrid III which remains the dummy of choice for safety organisations such as the National Highway Traffic Safety Administration (NHTSA) and safety testing organisations including Latin NCAP and Euro NCAP.

Lotta Jakobsson, Senior Technical Leader, Safety – Injury Prevention at Volvo, who specialises in biomechanics, told Megatrends, “The ambition is always to make dummies as biofidelic and anthropomorphically correct as possible.” She noted, however that, “It is essential that the physical dummies are repeatable tools, which poses challenges when aiming for maximum biofidelity.”

Thatcham Research is an accredited Euro NCAP testing laboratory, and Automotive Megatrends spoke to Matthew Avery, Thatcham’s Head of Research. He noted that a particular development is from ‘P’ dummies to ‘Q’ dummies, which are more biofedelic in particular areas that have been developed by Thatcham. “The frontal adults are the oldest and least biofidelic,” noted Avery, “but the new ‘Q’ child dummies are more biofidelic especially in the neck area than their forebears.”

Megatrends spoke to Alejandro Furas, Global NCAP Technical Director, who explained how Latin NCAP is also moving to the more biofedelic dummy in 2014 to ensure the effectiveness of its crash tests. “Until 2013, Latin NCAP was using a three-year old dummy and an 18 month old dummy, but they were from the ‘P’ family, which we see as a very old development. Later technology helped measure and understand how real-life children would be affected by a crash. With this later technology, a new family of ‘Q’ dummies was developed. We keep using the same ages of dummies but the ‘Q’ dummies have a higher biofidelity than the ‘P’ dummies.”

Types of dummy

Due to their limited biofedelity, crash test dummies are directional, which means a specific crash test dummy can only be utilised in one type of crash mode.

The main types of dummy are SID (Side Impact Dummy) specially designed to measure rib, spine and internal organ shocks and compression of the chest cavity in side collisions; BioRID, a development of the dummy which helps to more accurately assess whiplash trauma from a rear impact; and CRABI, which represents a child test dummy used to better measure the effectiveness of child restraint systems.

Child dummies still have some limitations, noted Jakobsson. “The most recent child dummy family “Q-series” is improved in many aspects as compared to its predecessors. However, they are still based on scaled-down adult data, putting limitations on biofidelity. There is still a great need for further research in this area.”

The BioRID was co-developed by Thatcham, has a very sophisticated articulated spine and is very biofidelic, but is only used for rear impact. In side impact, the new world SID has a more sophisticated multi axis chest that recently replaced the EuroSiD. Thatcham’s Avery said, “All dummies still have the issue that they are, in essence, single axis. A frontal dummy can only be used in a front crash, a BioRID only in a rear crash.”

Volvo Cars, like most OEMs, uses dummies supplied by Humanetics, the world’s leading producer of dummies. Jakobsson noted that most of the dummy developments are results of joint research projects, often between industry and universities and dummy manufacturers, and that Volvo Cars has been a part of several such projects. “In the mid-1990s we led the development of BioRID, the first dummy for evaluating whiplash injuries in rear end impact. We were also a part of the modifications of the most recent frontal impact dummy, THOR, providing biofidelity also in oblique occupant movements. This is especially essential for recreating real world frontal crashes which usually contain rotational kinematics as well.”

Adjusting the average

Mike Beebe, Senior Engineer at Humanetics, described to Megatrends how the organisation works with insurance and academic institutions to analyse the ever-increasing data generated by dummies. “This allows them to establish and prioritise the most common injuries, but also the most common victims,” said Beebe.

However, since the 1950s, the average person represented by Hybrid III has changed dramatically, and Humanetics needs to continuously evolve to develop prototypes for a dummy that better models the different types of human bodies.

When Hybrid III was introduced in 1976 it was designed to represent the ‘average’ American male, stood 1.8m (5ft 9in tall) and weighed 77kg (170lbs). Since then, that average male has gained more than 11kg (25lbs) and is 2.5cm (1in) shorter.

According to a recent study from the University of California Berkeley’s Safe Transportation and Research Education Center (SafeTREC), obese occupants are 78% more likely to die in a car crash than an average weight driver. To accommodate the increasing numbers of overweight drivers, Humanetics is developing an obese dummy. One prototype has already been produced that weighs 273 pounds with a body mass index of 35.

The God of crash test dummies?

Developing new dummies is difficult because they must react to massive impacts in the same ways the human body would, but must be durable enough to absorb scores from hundreds of crashes. This is why updating dummies as new materials and equipment become available is necessary to ensure their continued effectiveness.

“The dummies are continuously being improved,” noted Volvo’s Jakobsson. However, she also explained that the pace of improving dummies is quite slow and getting a new dummy on the market and accepted is a very long and difficult process. “Hence, few new dummies are developed over a ten year period. Most of the developments are refining the existing dummies, adding measurement possibilities and minor adjustments.”

The biggest upcoming change for dummies is an update of the frontal Hybrid III. Replacing these will be a new crash test dummy named THOR, which has been in development since the 1990s and stands for Test device for Human Occupant Restraint.

THOR is an advanced 50th percentile male dummy and successor of the Hybrid III model. It features an improved spine and pelvic structure in order to better resemble a human and comes with an innovative array of face sensors meant to determine how objects impact a human face during a car crash. Thatcham’s Avery explained, “THOR is currently in development and has been for a decade. We have announced the plan to adopt by the next decade, but it’s not yet fully developed.”

Despite THOR being filled with over 134 channels of data (78 more than Hybrid III), the industry is facing a chicken and egg situation, according to Avery, “because no one will complete development unless someone commits to use the dummy in testing.” He continued, “Committing is difficult since we are agreeing to use something we’ve yet to evaluate and this is especially problematic for vehicle manufacturers who need to develop their 2020 products next year but with a dummy they can’t buy.”

The death of the crash test dummy?

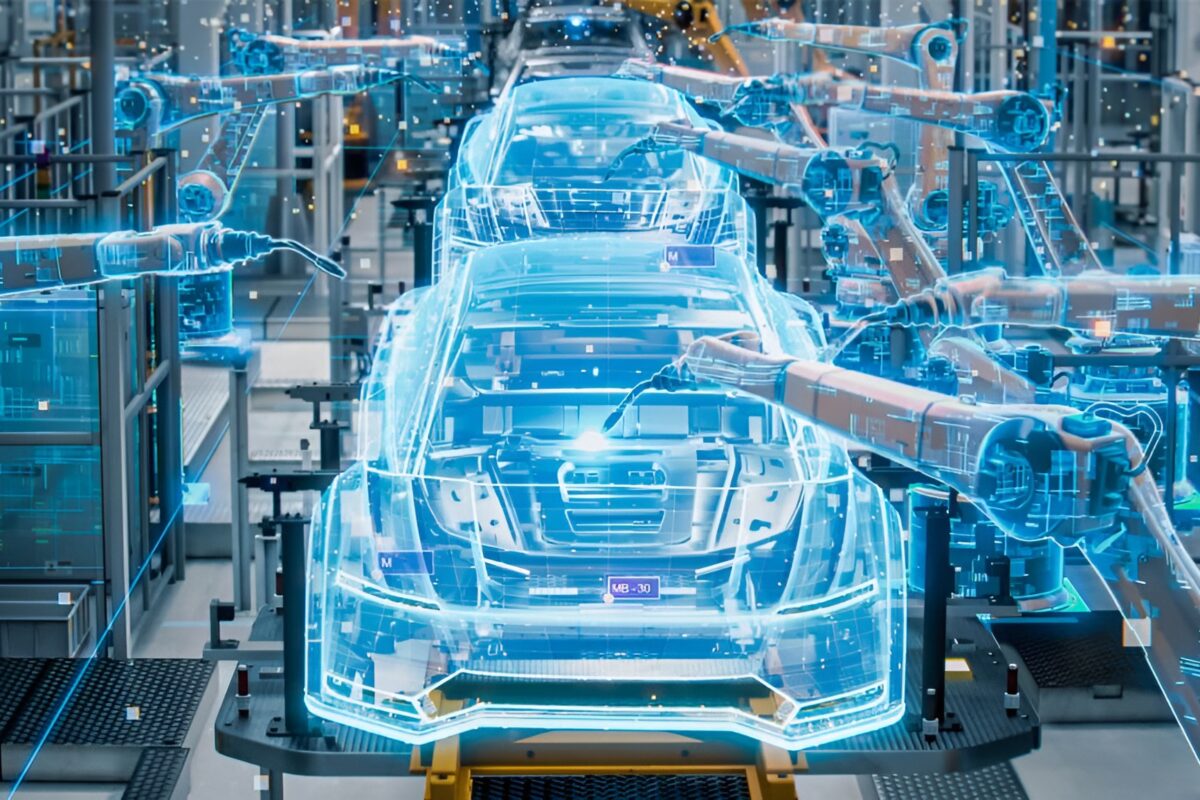

While the world of vehicle safety engineering is not ready to give up the crash test dummy in favour of the human computer model just yet, much work is being done in this area. Dr. Christophe Bastien, Principle Lecturer in Engineer Simulations at Coventry University in the UK spoke to Megatrends about the potential for the future crash test dummy to lie in the virtual rather than the physical world.

Bastien noted that thanks to crash test dummies, the level of fatalities on the road in the last 30 years has improved greatly, and suggested that we need crash test dummies to provide pointers to engineers to design safer vehicle structures. However, Bastien, who has spent his career working in occupant safety, also suggests that crash test dummies are nevertheless machines which record acceleration, displacement and forces. “These metrics are linked with injury criteria which are used to predict, statistically, risks of injuries. As a crash test dummy needs to be used many times, it has to be repeatable and unbreakable, which is contradictory to a human being.” Because of this, Bastien explained that dummies are not surrogates for human beings, and that some metrics in the crash test dummies are still deliberated, like the Head Injury Criteria (HIC), which is challenged by the Brain Injury Criteria (BrIC) proposed as a potential candidate by NHTSA. This includes the rotational effect of the brain in the injury instead of a simple linear translation. Another metric is the neck injury criteria as they have little to do with real trauma injuries. “The sentiment to use these metrics goes in the right direction for safety: they are practical to measure and engineer for. Nevertheless this is still unsatisfactory: only human models can answer trauma injuries.”

Bastien argues, therefore, that crash test dummies are limited and “should be accepted as they are: they will never be biofidelic.” He explained to Megatrends that despite huge changes in biofidelity of dummies, “Even the new WorldSID and THOR are not as biofidelic as human models. I do not envisage them to ever be active and tense their muscles prior to crash or to create evasive manoeuvres for example.”

Volvo’s Jakobsson agrees, believing that the future changes of physical dummies will go in-line with the developments today, anticipating a relatively slower pace with respect to physical dummy developments, since virtual human body models are more in focus and provide many benefits. She said, “I think the physical dummies mainly will improve with respect to sophistication in measurement technique – adding more injury types to be monitored and predict. I also foresee some developments in enhanced biofidelity and possibly in some more dummy sizes.”

Jacobsson noted that the major steps regarding developments of tools for humans in a crash are soon to be taken in the area of virtual human developments. “Today we have a number of human body models, comprising more humanlike body representation including skeleton and internal organs for example. This development will continue rapidly and we will get more sizes and more detailed injury prediction capabilities.”

Despite these steps, she noted that these virtual human body models cannot be transferred into physical crash test dummies, since they are too complex. “Therefore, we also need developments in virtual verification and/or consumer information testing in order to effectively use these sophisticated human representatives in a wider context than in-house vehicle development and research areas.”

So how long will steel-skeletoned, rubber-skinned dummies be part of crash testing? The truth is, the future of physical dummies may be uncertain. Bastien believes that while in the future, physical dummies should still be used to validate and calibrate the occupant’s interaction with the airbag and restraint system at the beginning of the vehicle design. However, once this is completed, Human Computer Models (HCMs) realistically could be used to investigate occupant percentile variations, age variations, gender variations, children variation, obesity (BMI) variations, muscle tension in pre-braking, and to fine tune the vehicle for humans and not crash test dummies. The move towards computerised dummies for crash tests, therefore, may not be far away.