The connected car will require OEMs to sift through a lot many more lines of code than ever before. Verifying its ability to perform will become both increasingly important, and increasingly complex. If cars really are going to become smart phones on wheels, the automotive industry is going to need all the help it can get.

That’s the view of Kishore Rao, Managing Director for Mathworks India, who identifies this as one of the key trends that will shape his company’s strategy. Mathworks, a developer of technical computing software, serves a number of industries, but it’s within automotive where it currently finds itself most in demand.

For Rao, the trends driving the industry make it a great place for a tech company to be, particularly as technology becomes more affordable, and high tech systems are scaled down across all segments. A shift in focus from passive to active safety, says Rao, will see advanced driver assistance systems (ADAS) become features in entry-level cars. A combination of falling costs and legislative measures will see blind spot monitoring, advanced emergency breaking and pre-collision warning come as standard.

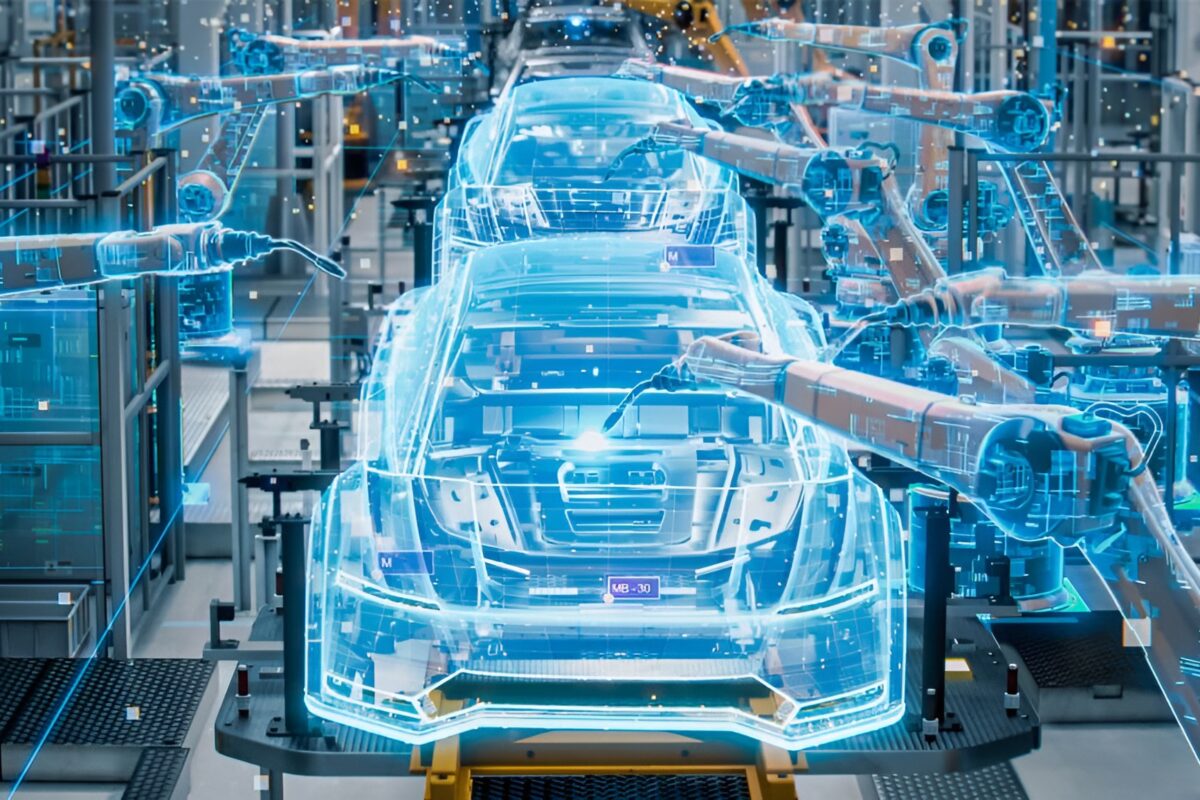

Mathworks specialises in the development of model- based design systems, with its two key platforms dubbed MATLAB and Simulink. The former allows for the modelling of vehicle sub-systems, such as safety systems, body electronics, infotainment systems and powertrains. Simulink then allows for simulation of these models. Once a system is run through simulation, it can be taken down to production. Combined, the two systems cater to two important demands from OEMs – reduction of time to market, and system verification.

Get it right first time

“Systems today are already extremely complex,” says Rao. “For example, if you look at powertrain systems, and particularly hybrid systems, they’re extremely sophisticated and composed of multiple system domains – chemical, electrical, mechanical and physical, between all of which there is increasing interaction. It is extremely very difficult to design something like that without being able to completely model and simulate them in the model- based design environment.”

In particular, the advent of autonomous driving, ADAS and vehicle connectivity will see an exponential rise in the complexity of on-board software. Model- based design, says Rao, is going to become a standard framework for all OEMs. Increased connectivity and use of electronics will mean that the further down a line a bug or error can travel, the more costly and time-consuming it will become to rectify. Manufacturers will require access to tools that can detect them as early as possible.

“We’re already at a stage where a lotmany of the controls in vehicles today are managed by software or electronics,” he says, “and where that is the case, you need to make absolutely sure that when your vehicle is out there in the market, it performs exactly the way you’d like it to. Products like ours allow OEMs to verify their systems, which dramatically reduces the number of errors and bugs. We call this is early verification, where you’re able to verify early in the design process. This is the core benefit, as it directly impacts the time to market and the overall cost of development.”

Shortening the cycle

Rao feels that driving down time to market will only become more important as tech giants such as Apple and Google begin to make their presence felt in the automotive industry. Whilst it’s not yet clear whether either company is going to put cars on the road, Rao believes feels its apparent they do want a role in vehicle technology ownership. “They’re going to look to accelerate technology adoption in vehicles,” he says. “After all, they’re consumer goods companies.”

Such concerns should also remind OEMs that ways of integrating the lightning quick pace of technology development cycles into the comparatively sluggish model design cycle still require development. “This is something that’s already happening,” says Rao. “If you look at our local Indian market, we may not be as advanced as Western markets, but even here you can see that the leaders of the pack are the ones with very short development times, and these times are always shrinking.”

Making sense of the senses

The connected car, and the increased use of sensors and cameras, will is going to keep tech firms like Mathworks extremely busy. Sensors are only as good as the software that analysesing what they can gather, and the role for Mathworks will be to further enhance a vehicle’s ability to leverage the information it can gather.

“For example,” says Rao, “both radar and vision sensors are a key part of a typical ADAS setup. There are specific tools for image processing and video processing. Our tools make it possible to bring what we call sensor-fusion, which means integrating the data gathered from radar sensors with that gathered with vision sensors.” In turn, he continues, this can help OEMs to develop the increasingly complex algorithms that ADAS technology requires, particularly as further sensors are introduced.

ADAS development will also require a firm like Mathworks to further collaborate with others in the tech sphere. In particular, the development of advanced display systems used by ADAS requires Mathworks, whicho operates on the logic side, to provide solutions that can be integrated with graphics and interface solutions. “Customer expectations mean that advanced display systems and infotainment systems are only going to become more complicated,” he says, and collaboration will be essential in producing systems that can respond to what a customer does, and modify its functions and behaviour accordingly.

Such is the versatility of Mathworks’s products that Rao sees opportunities beyond assisting in connectivity and safety developments, such as in improving fuel-efficiency, and powertrain electrification. “That’s the good thing about model- based design,” he says. “It’s something that’s been established over the last few decades, and has been developed into a framework that has potential in all of the current concerns that OEMs have.” As time goes on, he concludes, and as tech firms become further integrated into the automotive industry, companies like Mathworks will be called upon to help OEMs face up to new challenges.